WEBINAR: So nutzen Sie die AODD-Pumpentechnologie zur Verbesserung der Verarbeitung

JETZT AUF ANFRAGE ERHÄLTLICH

Das Herzstück jedes Prozesses sind Pumpen, die mit Qualität, Erfahrung und Innovation hergestellt werden.

Wenn es darauf ankommt, zählen Sie auf Unibloc®.

Wir helfen Ihnen, Ausfallzeiten und kostspielige Umbauten zu vermeiden. Unsere

präzisionsgefertigten, hygienischen Verdrängerpumpen nach höchsten hygienischen Standards

übernehmen die sensibelsten Hygienearbeiten. Wir entwickeln einfache, leicht zu reinigende Pumpen, die Ihren Betrieb am Laufen halten.

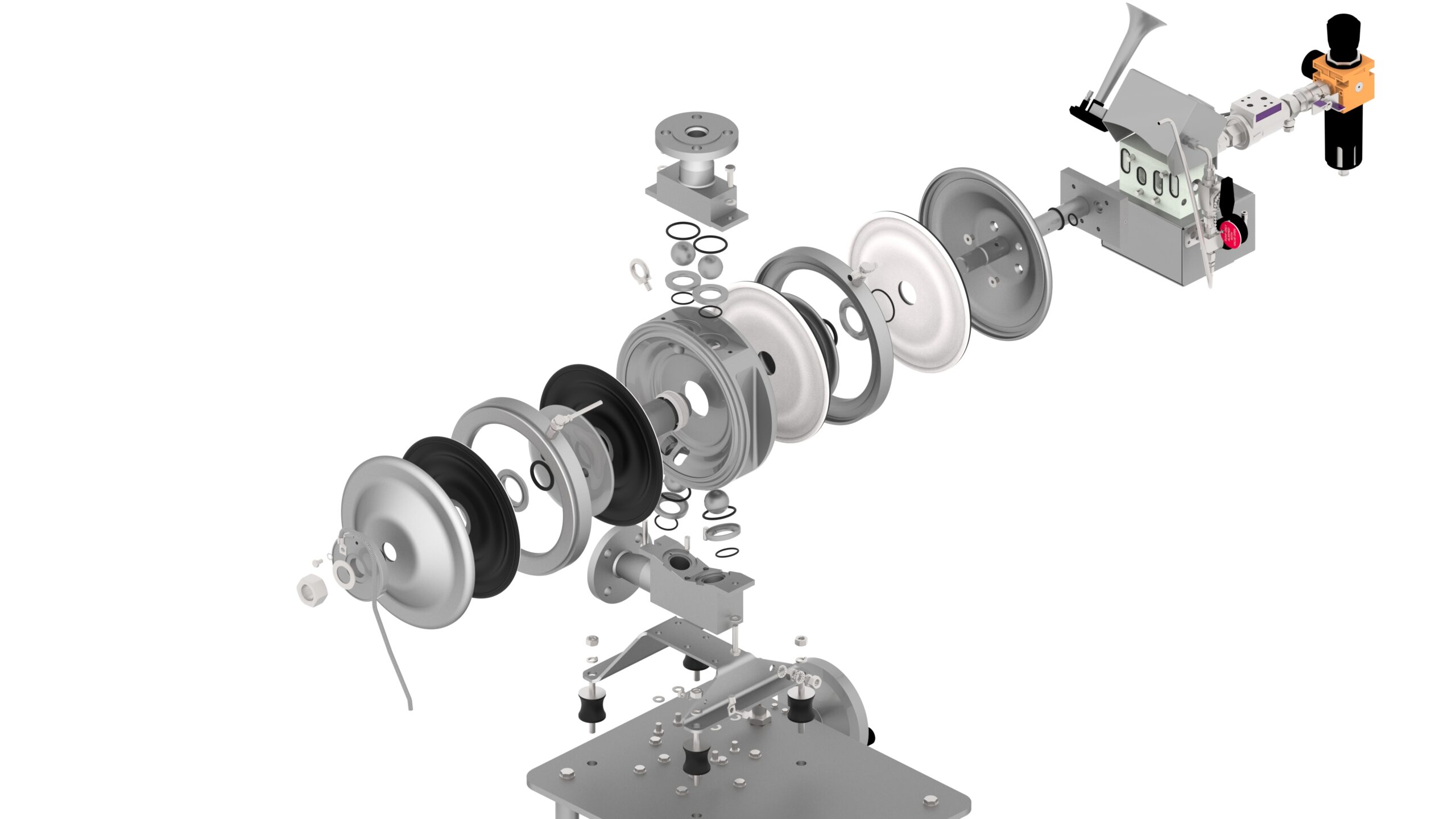

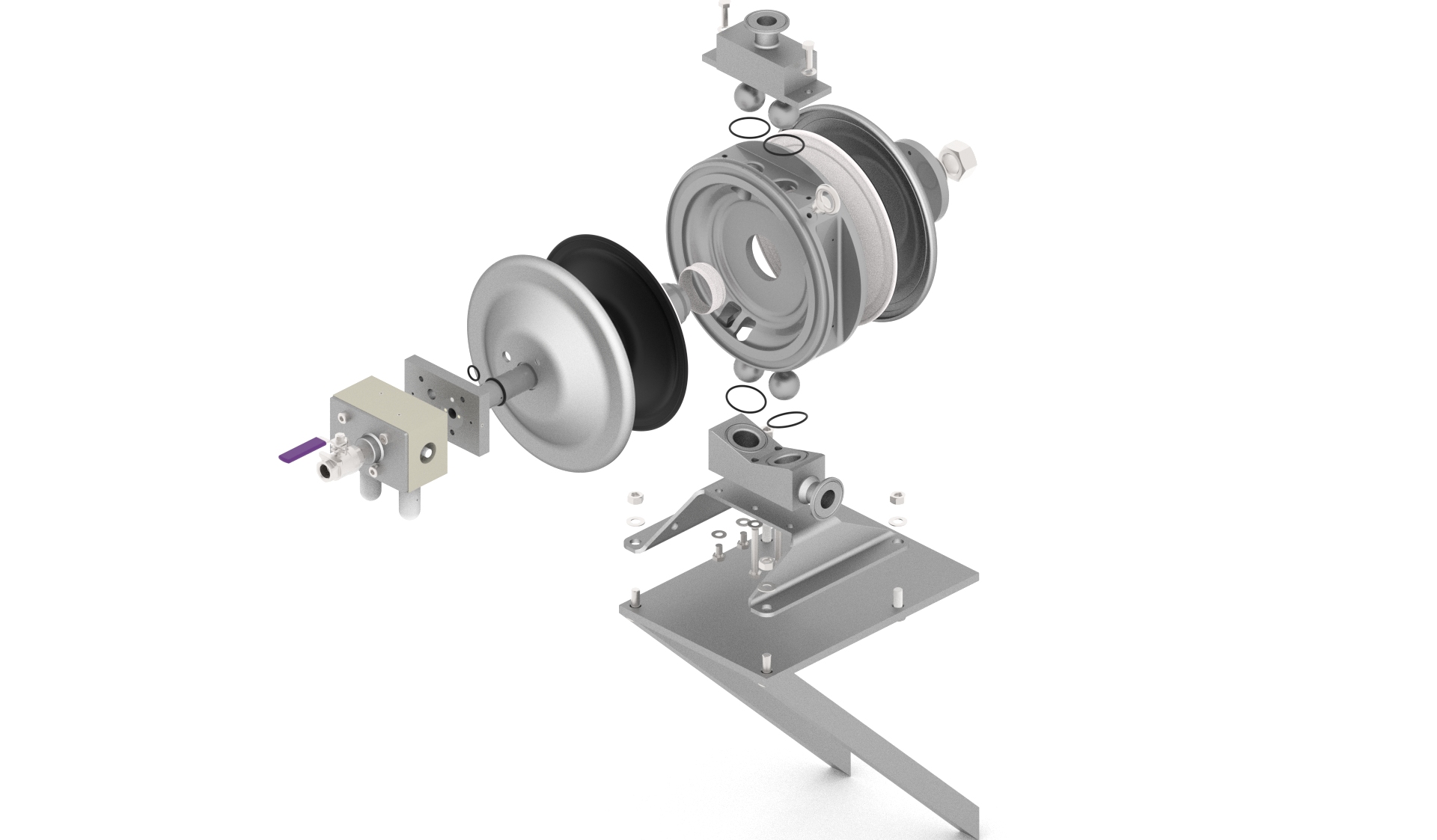

Pionierarbeit bei der luftbetriebenen Doppelmembranpumpe mit einer Mutter

Reduzierung von Ausfallzeiten durch vereinfachte Montage und Demontage, Einsparungen durch einfachere Wartung und Bereitstellung erstklassiger CIP-Leistung.

Hygienic Produkte zur Flusskontrolle, auf die sich Kunden verlassen

Bewältigen Sie die härtesten Aufgaben mit überlegenen Produkten von Ventilen, Schaugläsern, Blasenfallen, Sieben, Ölkühlern und mehr – und stellen Sie gleichzeitig unsere strenge Qualitätskontrolle.

Sicherheit kommt Standard

Standard Pump Produktlinien stehen für hochwertige industrielle Fasspumpen, auf die sich Kunden in mehr als 50 Ländern verlassen.

Unibloc – Der Pumpen-Innovationsführer

Die präzisionsgefertigten Verdrängerpumpen von Unibloc sind Ihre Lösung für die anspruchvollsten Anwendungen der Branche

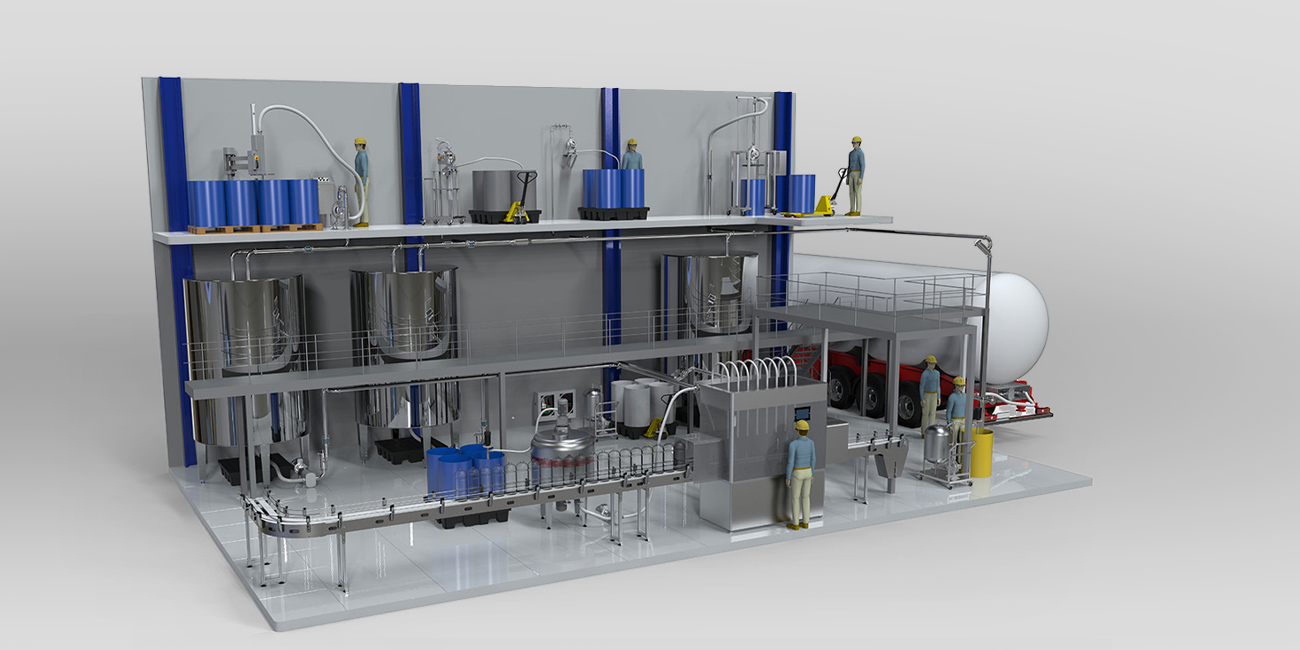

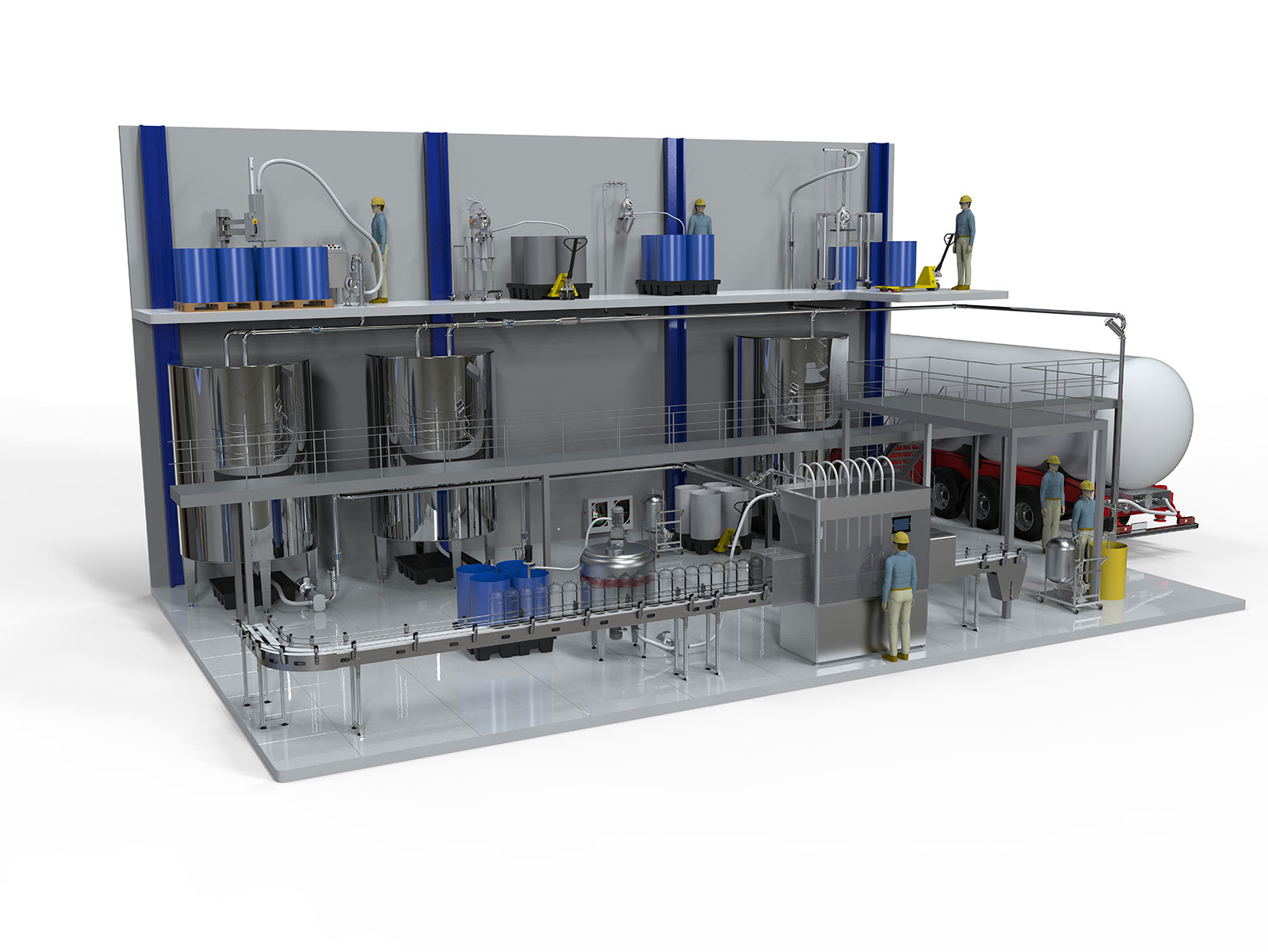

Die interaktive Verarbeitungsanlage

Unibloc Hygienic Technologies Sind Sie von der Laderampe bis zur Verarbeitung abgesichert?

Wählen Sie eine Markierung im Bild aus, um mehr zu erfahren.

In der Produktion steht ein 12-Zoller FlotronicDie schlanke Sanitärpumpe ® 3A nimmt nur wenig Platz ein, da sie das Produkt durch das Entladesystem des Auslegerarms zum Behälter auf der darunter liegenden Ebene befördert. Entwickelt für Clean-in-Place (CIP), das proprietäre Verfahren der Pumpe One-Nut®-Technologie ermöglicht eine einfache Wartung für Lebensmittel- und Pharmaanwendungen mit strengen Hygieneanforderungen.

Ein 10-Zoll-Slim Flotronic® One-Nut® Sanitär-Slim-Pumpe bietet Produktionsflexibilität als mobile Lösung, wenn sie auf einem verstellbaren Rollwagen montiert wird. Hier wurde es positioniert, um ein Fass in das darunter liegende Gefäß zu entleeren. Ausgestattet mit einem Guardian-Alarmsystem bietet es einen sofortigen Schutz, um die Pumpe abzuschalten und das Medium einzudämmen, falls eine Membran bricht.

Ein wandmontiertes 10-Zoll-Slim Flotronic®-Pumpe schafft auf verschiedene Weise Platz für zusätzliche Produktion; Durch die Wandhalterung wird wertvoller Platz auf dem Boden frei, das schlanke Profil nimmt nur minimalen Platz ein und ermöglicht es dem Anlagendesign, Produktleitungen an der Wand zu platzieren.

Das Flotronic® Fassentladesysteme beinhalten unser einzigartiges One-Nut® hygienic/Sanitärluftbetriebene Doppelmembranpumpe (AODD) mit Fassentladekufe. Es kann die Pumpe für einen einfachen Austausch anheben oder absenken und ermöglicht eine Rückgewinnung von bis zu 99 % hochviskoser Materialien bei erhöhten Durchflussraten.

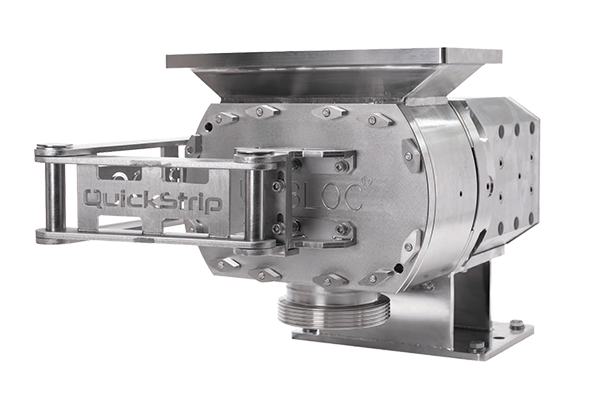

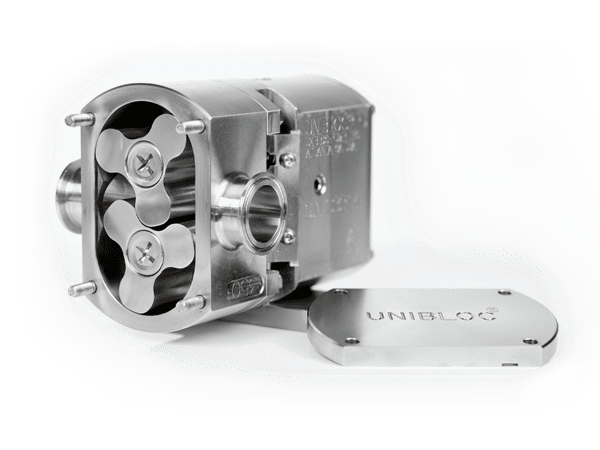

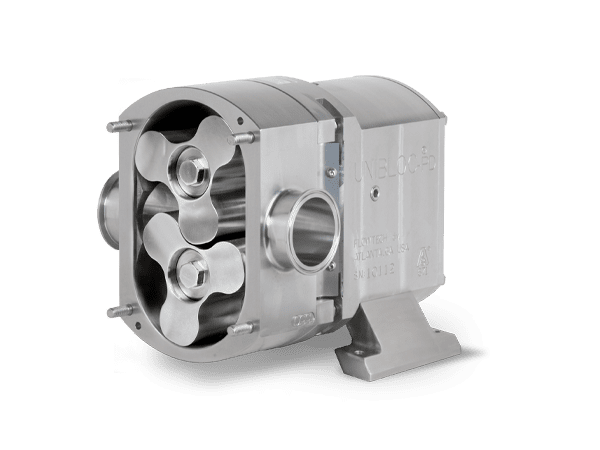

Unsere Zahnradpumpenserie ist die erste Wahl für viskose Materialien in 3A-Sanitäranwendungen und verfügt über präzisionsgefertigte Spiralzahnräder für einen reibungslosen, effizienten und leisen Betrieb. Unser patentiertes QuickStrip® Design ermöglicht den werkzeuglosen Zugang zu Pumpenköpfen und Dichtungen und reduziert so Ausfallzeiten und Arbeitsaufwand für Wartung und Hygiene.

Die beiden Gefäße enthalten a Unibloc Die Drehkolbenpumpe der PD550-Serie setzt Maßstäbe in der Branche standard für Hochleistungs-Sanitärpumpen. Es bietet eine gleichmäßige, scherarme Leistung, die die Produktintegrität für eine Vielzahl anspruchsvoller Anwendungen aufrechterhält. Die Pumpleitungen verlaufen unter dem Laufsteg in die Rückseite der Abfüllmaschine. Unibloc 550 Pumpen eingebaut QuickStrip®-Technologie mit patentiertem Schwingarmdesign zur Reduzierung der Wartungszeit.

Auf Tanktransport-Profis zählen wir Unibloc Hygienic Technologies um robuste und zuverlässige Chemie- und Lebensmittelpumpen bereitzustellen. Seit über 35 Jahren Unibloc hat unsere Tankwagenpumpen weiterentwickelt, um die Zuverlässigkeit und Langlebigkeit zu gewährleisten, die von vertrauenswürdigen Flotten erwartet wird.

Unsere Hygenitec Sanitär-Fasspumpen liefern eine sichere, effiziente und hygienic Methode zum Übertragen von Zutaten aus Fässern und Intermediate Bulk Containern (IBCs) zur nächsten Verarbeitungsstation.

Wir liefern die stärksten präzisionsgefertigten Zahnradpumpen der Branche, wobei jeder Pumpenkopf aus massivem 316L-Edelstahl besteht. Hier fördert eine Zahnradpumpe das Produkt vom Mischbehälter in den Trichter. Spiralverzahnte Zahnräder sorgen für einen reibungslosen und leisen Betrieb. Unser QuickStripDas ®-Design mit Einwegmontage verringert Schäden durch Fremdmaterialien und sorgt für einen längeren, langlebigen Betrieb.

Sanitär-Inline-Schaugläser sind in verschiedenen Größen, Glasmaterialien und Druckbereichen erhältlich, um Sicherheit zu gewährleisten und gleichzeitig eine visuelle Überwachung des aktiven Prozesses zu ermöglichen. Unsere Doppelmutterspannung positioniert das Schauglas sicher, ohne es zu fest anzuziehen.

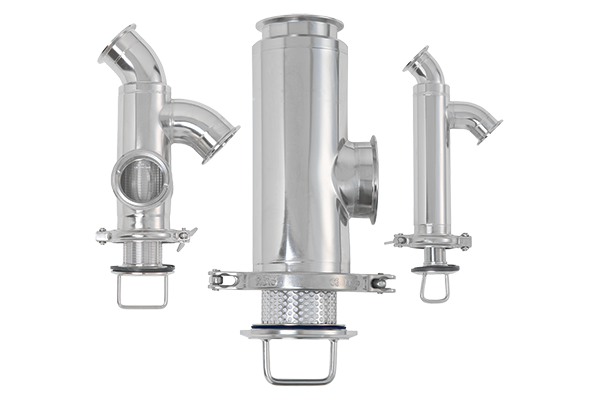

Inline-L-Siebe sind präzisionsgefertigt und erfüllen pharmazeutische Qualität standards für Betriebe, die ein hohes Maß an Hygiene erfordern. Erhältlich in Edelstahl 316L oder Hastelloy standard Größen oder unsere Hochleistungsserie für höhere Durchflussraten, Produkte mit höheren Viskositäten oder Unternehmen, die eine Lösung für minimalen Druckabfall suchen. Die individuelle Anpassung des Siebkorbs ermöglicht eine Auswahl an Siebgrößen und Maschenweiten sowie kundenspezifische Ablassöffnungen.

Unsere hohe Kapazität hygienic Y-Siebe sind in einer Vielzahl von Leitungsgrößen erhältlich, von 0.75 Zoll bis 6.0 Zoll. Ein Inline-System ermöglicht es den Arbeitern, den Filter zu reinigen, ohne ihn aus der Rohrleitung zu entfernen. Erzielen Sie mit dem bidirektionalen Durchfluss die gewünschte Vielseitigkeit und das gewünschte Volumen. Die 360-Grad-Montagemöglichkeiten für Geräte tragen dazu bei, Platz zu sparen und ermöglichen eine größere Flexibilität.

Übertragen Sie korrosive Chemikalien, wie sie in CIP- und/oder COP-Prozessen verwendet werden, sicher aus Fässern, IBCs und Behältertanks mit einem Standard Industrielle Fasspumpe.

Unser Sanitär-Druckbegrenzungsventil verfügt über eine unkomplizierte, hygienic SimpleSet-Design, das eine einfache Druckeinstellung ermöglicht. Ventile sind in verschiedenen Größen erhältlich und auf Drücke von 10 bis 200 psi einstellbar. Das CIP-Design ermöglicht eine einfache Reinigung.

Unibloc LKW-Pumpen bieten eine zuverlässige, lebensmitteltaugliche Pumpe, die für anspruchsvolles tägliches Be- und Entladen entwickelt wurde. Leicht zu pflegen. Die zuverlässigsten und langlebigsten O-Lippen-Wellendichtungen der Branche verhindern Lecks.

UNSERE PUMPEN SIND DAS HERZSTÜCK UNTERNEHMENSKRITISCHER PROZESSE

Entdecken Sie unsere Produkte

Präzise gearbeitete hygienische Pupen, druckluftbetriebene Pumpen, Fasspumpen und mehr aus unserem gesamten Sortiment der Unibloc, Flotronic und Hygenitec Marken. Alles UHT hygienic Pumpe werden mit höchster Qualität gebaut und bewähren sich zuverlässig in den anspruchsvollsten Umgebungen

Produkte ansehenUnibloc Industriepumpen von Hygienic Technologies sind bewährte Leistungsträger sind bewährte Leistungsträger für Ihre härtesten Industrieanwendungen.

Produkte ansehenEntwickelt für eine Vielzahl an Anwendungen bieten wir eine vollständige Auswahl an hygienischen Ventilen, einschließlich Überdruckventilen, Rückschlagventilen und Absperrventilen

Produkte ansehenDie größte Auswahl an hygienischen Y- und L-Sieben in Standardgröße und für Konfigurationen mit hoher Kapazität.

Produkte ansehenSanitäre Schaugläser, erhältlich in verschiedenen Größen, Glasmaterialien und Druckbereichen, bieten Ihnen zusätzliche Effizienz und Schutz bei der Überwachung Ihres aktiven Prozesses.

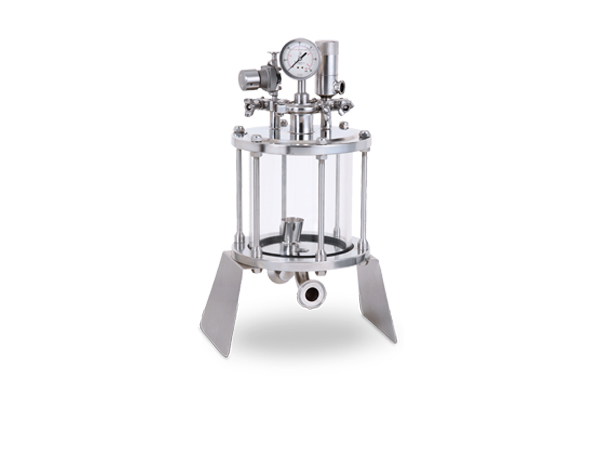

Produkte ansehenEntwickelt, um Lufteinschlüsse während der kritischen Chromatographieprozesse zu entfernen, unsere hygienic Blasenfallen zeichnen sich durch ein ultra-sauberes und montagefreundliches Design aus. Wir bieten eine große Auswahl an Größen und Anschlusskonfigurationen.

Produkte ansehenUnsere innovativen Ölkühler sind für eine sichere, einfache Wartung und maximale Leistung auf lange Sicht ausgelegt.

Produkte ansehenMöglicherweise haben Sie es mit einem AODD versucht. Aber das ist nichts wie ein Flotronic AODD+. Mehr erfahren

Einkaufsführer für Lebensmittel und Getränke

Das Recht auswählen hygienic Pumpe ist sowohl für die Einhaltung als auch für die Aufrechterhaltung der Lebensmittelsicherheit/Produktintegrität von entscheidender Bedeutung. Holen Sie sich unseren Einkaufsführer, um die zu berücksichtigenden Faktoren bei der Pumpenauswahl, die erforderlichen Konstruktionsspezifikationen und Fallstudien zu sehen.

Holen Sie sich den Leitfaden

Whitepaper: Ausfälle von Pumpendichtungen 101

Ausfälle von Pumpendichtungen – warum treten sie auf und wie können Sie sie verhindern? Pumpendichtungen sind eine kritische Ursache für Pumpenausfallzeiten und kostspielige Reparaturen. Unser Whitepaper erörtert Ursachen und Maßnahmen zur Vorbeugung, die Sie ergreifen können.

Holen Sie sich Whitepaper

BLOGEINTRÄGE

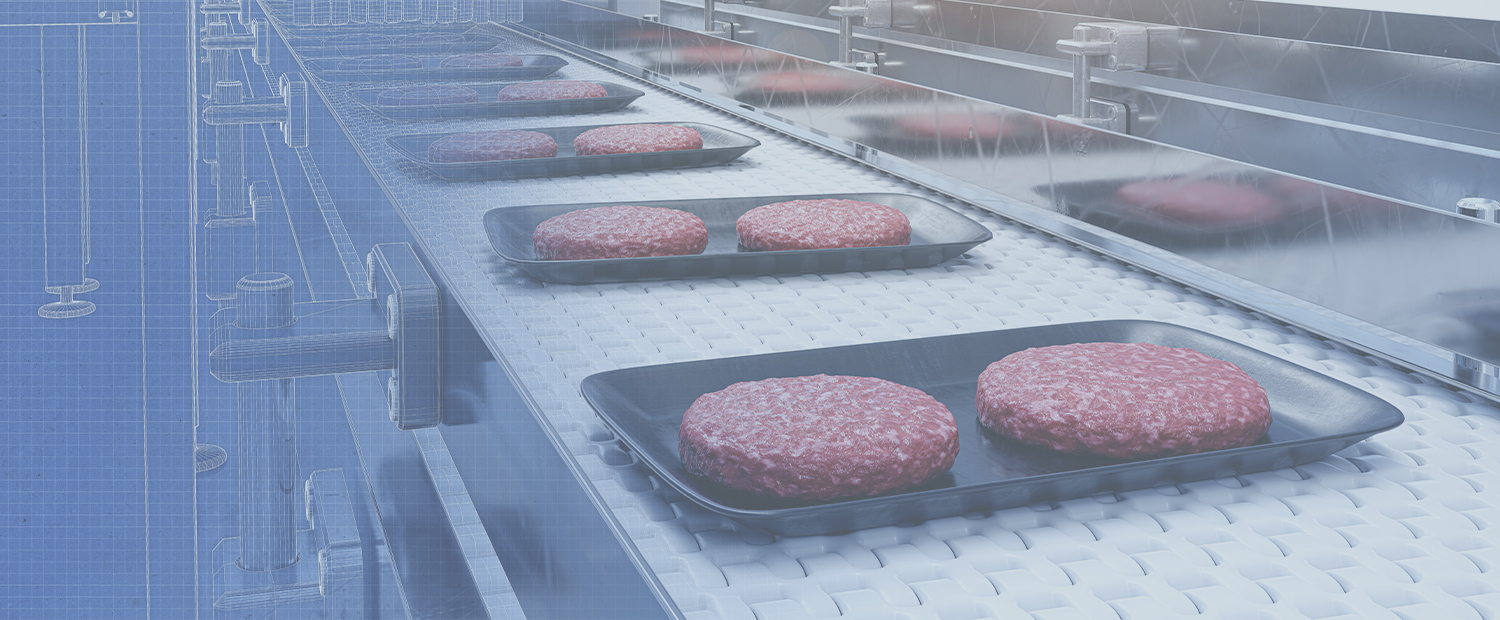

Die Vielfalt der verfügbaren Rind- und Schweinefleischprodukte nimmt ständig zu, um dem Wunsch der Verbraucher nach Komfort und Auswahl gerecht zu werden. Je moderner die Verarbeitungsanlage ist, desto besser können Werksleiter und Industrie mithalten. Dennoch ist die Automatisierung nicht so weit verbreitet, wie es scheint, und aufgrund von Budgetbeschränkungen müssen Unternehmen danach suchen technologies die ihre Geschäftsabläufe auf erkennbare Weise verbessern können.

Zum BlogpostWie einige Fleischverarbeiter Arbeitsprobleme mithilfe von Technologie angehen

Rind- und Schweinefleischverarbeiter haben viel zu tun. Sie müssen nicht nur die Produktionskosten niedrig halten, sie müssen dies auch tun und gleichzeitig die Herausforderungen bewältigen, die sich aus einer knappen und gering qualifizierten Arbeitskraft ergeben. Dieser Blogbeitrag behandelt:

Zum BlogpostMinimierung von Lebensmittelsicherheitsrisiken bei der Fleischverarbeitung: Die Rolle von Hygienic Pumps

Während die meisten Menschen auf das neue Jahr 2024 anstießen, feierte der Lebensmittelsicherheits- und Inspektionsdienst des USDA nicht. Beamte wiesen Valley Meats an, fast 7,000 Pfund rohes Hackfleisch zurückzurufen, bei dem Labortests ergaben, dass es mit E. coli O157:H7 kontaminiert sein könnte. Obwohl keine Krankheiten gemeldet wurden, kann das Bakterium schwere Verletzungen und sogar den Tod verursachen. Der Rückruf erinnerte die Rind- und Schweinefleischverarbeiter an die Bedeutung von Sicherheitspraktiken und hygienic Anlagenausrüstung.

Zum Blogpost